FLEX PASTE®

SUPER THICK RUBBERIZED PASTE

Now in our Stay Fresh Container!

FLEX PASTE® is a super thick rubberized paste that you can spread, shape, form, and seal virtually everything. It starts out as a thick paste and dries to a strong, flexible, waterproof barrier that can be applied to all types of surfaces to seal out air, water, and moisture. It clings to the surface and instantly fills large gaps, cracks, and holes. It won’t shrink or wash away and can be painted any color. Can be applied on dry or wet surfaces, even underwater!

NEW FLEX PASTE CLEAR

Flex Paste is now available in Clear! A crystal clear, super thick rubberized paste that clings to virtually any surface, instantly sealing out water, air, and moisture with an invisible finish, ensuring that the original look of your projects remains unchanged. It’s perfect for filling large gaps, cracks, and holes, creating a strong, flexible, and waterproof seal. With its Advanced Hydrophobic Formula, Flex Paste® Clear also works underwater!

FLEX PASTE IS PERFECT FOR:

• Fix cracks and holes

• Foundation and concrete repair

• Seal out rodents and pests

• Bath and shower repair

• Indoor and outdoor projects

• Roof repair

• RV and motorhome repair

• Auto repairs and boat repairs

• Lawn and garden projects, and more

Works on: Wood, glass, tile, concrete, aluminum, metal, brick, stucco, masonry, copper, fabric, fiberglass, ceramic, porcelain, natural stones, roofing, PVC, EIFS, EPDM, CSPE, Hypalon polyurethanes and much more.

Available in white, black and clear.

Caulk gun required to use cartridges.

DRY TIME

FLEX PASTE begins to cure once exposed to air, moisture & humidity and will skin in 15 to 30 minutes. Allow each coat to dry before applying additional coats. FLEX PASTE cures in 24 to 48 hours and gets stronger over time.

*Review count based on 5 star amazon.com reviews, collected between June 2020 and December 2023, and 5 star Bazaarvoice reviews from our retail partners, collected between April 2020 and December 2023.

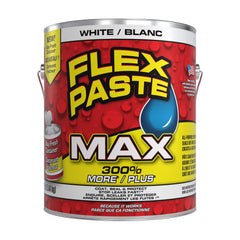

63% savings for Flex Paste MAX based on price per oz, compared to our 9 oz size.

Product sizes and colour availability:

Flex Paste Clear

- Cartridge 9 oz / 270 mL (caulking gun required)

- US Half-Quart 8.75 oz / 258 mL

- Half-Quart 26 oz / 760 mL

- MAX Not available in Clear

Flex Paste Black and White

- Cartridge 9 oz / 270 mL (caulking gun required)

- US Half-Quart 1 lb / 454 g

- US Quart 3 lb / 1.36 kg

- MAX 12 lb / 5.44 K

For complete instructions go to: How To Use Flex Paste

Read entire label for directions and warnings before use.

Protective clothing & eyewear are recommended. Do not shake or stir product. Surface must be free of grease, oil & dirt.

For Flex Paste in the original (plastic) container

Remove silica gel packet and slowly lift protective foil from the surface. Do not discard foil or silica gel packet!

After each use, press the foil onto the center of the remaining material and continue pressing outward so the foil remains in contact with the material. As foil reaches the edge of the tub, press around the inside perimeter, keeping the excess foil up. Replace silica gel packet and secure the lid tightly.

For Flex Paste in the original stay-fresh container

Remove lid. Place lid on top between applications. Secure Lid after project completion.

Once opened, product will begin to cure. To slow the curing process, keep product covered (with lid) during use. Secure the lid and store in a cool dry place when done.

DIRECTIONS

• Using putty knife, trowel or similar tool, remove an even layer from the top surface.

• Do not scoop deeply into the tub as this may create air pockets.

• Apply a generous amount to the surface using a smooth motion.

• Etching the surface will increase adhesion.

• Sanding is not recommended – instead, smooth to desired finish or add designs to create unique artistic textures.

• Always make sure all cracks & holes have been completely filled & cured before testing.

CLEAN UP

Use a cloth with mineral spirits or acetone to clean your tools and work area. Do not use water.

Before reuse, remove any dried material that may have formed on the inside perimeter of the tub or on the surface. Store in a humidity-controlled environment.